Revolutionizing Precision Manufacturing with Node-RED

Node-RED has immensely facilitated our work. The tool's versatility and development speed have allowed Abrasive Technology to tackle projects that might have been deemed out-of-reach or discouraging in the past. It also allows us to develop our applications in a platform agnostic way that is much more flexible and agile in terms of hardware selection and adaptability.

In the competitive world of manufacturing, where precision, innovation, and efficiency reign supreme, Abrasive Technology has emerged as a global leader in super-abrasive tooling and coatings for a wide variety of applications.

This case study provides an in-depth exploration of how Abrasive Technology harnessed the power and flexibility of FlowFuse and Node-RED to optimize automation, streamline communication with machinery, and accelerate development processes.

# Organization Profile

Abrasive Technology stands as a beacon of innovation in the manufacturing sector, boasting a global presence with approximately 300 employees across all of its facilities. With a focus on diverse sectors including industrial, aerospace, dental and medical, Abrasive Technology has positioned itself as a key player in the industry. Headquartered in Lewis Center, OH and with significant operations in the UK, the company is at the forefront of cutting-edge manufacturing. Abrasive Technology's exemplary work extends to world renowned, tier 1 aerospace suppliers and throughout a wide array of manufacturing.

# Challenges

Navigating the intricacies of manufacturing across various sectors posed unique challenges for Abrasive Technology. Seeking solutions to automate processes, enhance communication with machinery, and improve overall efficiency became imperative. Josh Dudley, a pivotal figure in the organization, reflects on these challenges: "We might have eventually accomplished certain tasks without Node-RED, but it makes these solutions quickly attainable. It empowers us to embark on projects that might have been discouraging in the past."

# Node-RED Integration

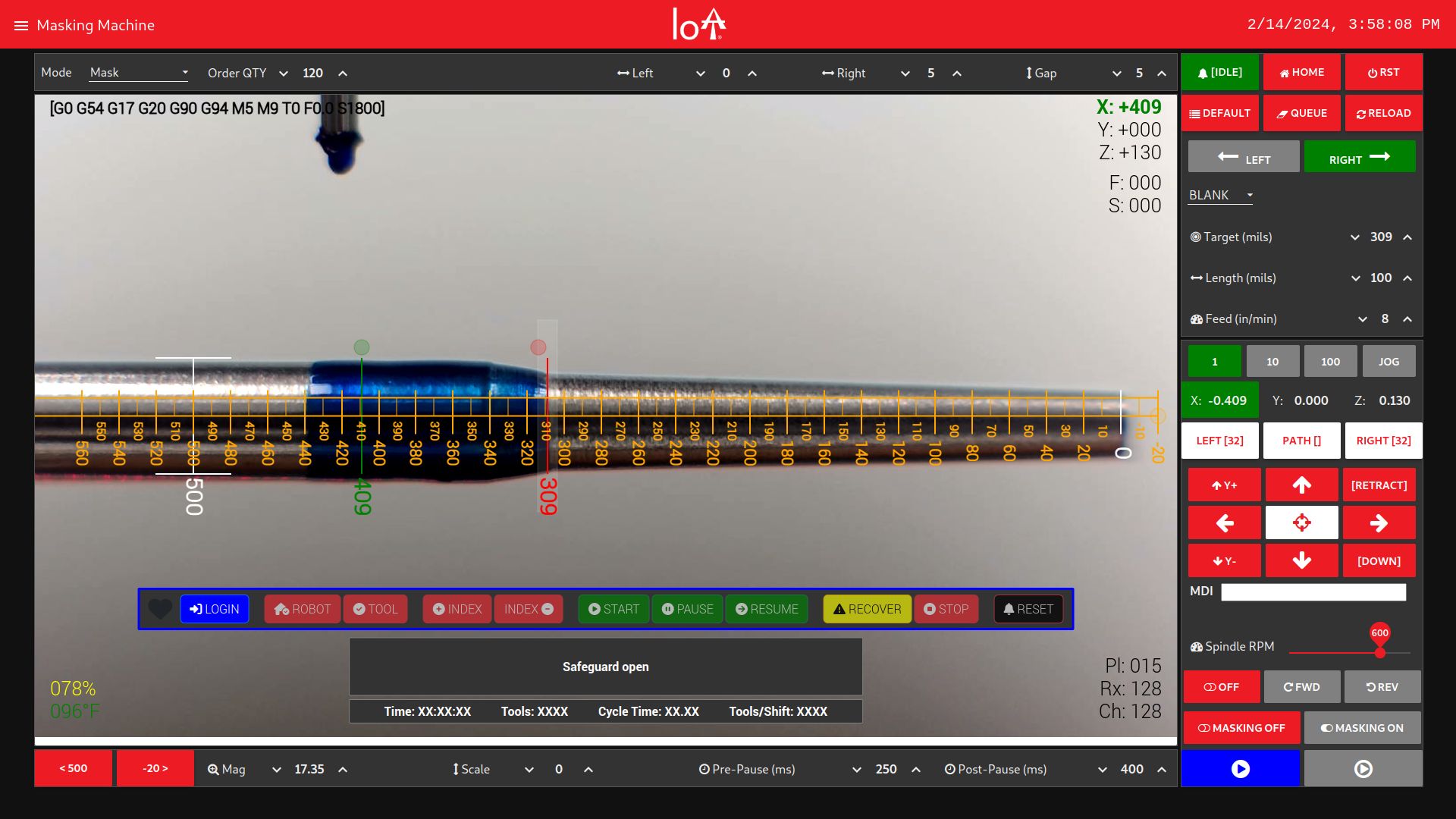

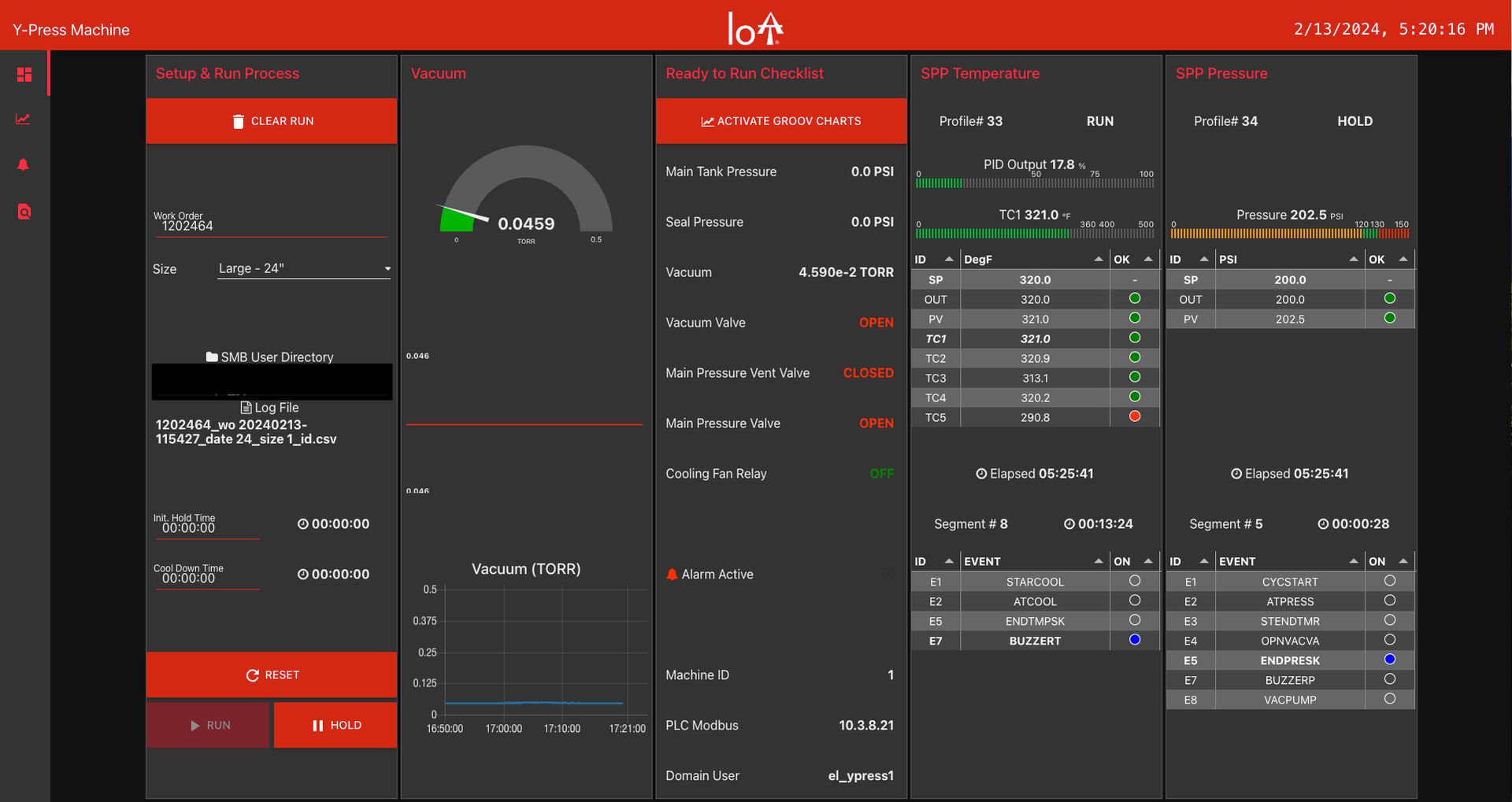

Abrasive Technology has more than five decades of history of embracing and adopting new technology to achieve its goals and serve its customers. Dudley, a key player in this technological evolution for the past two decades, became an early adopter of Node.js running on 1st generation Raspberry Pis for machine automation and monitoring back in 2012. In 2019, an experimental automation project marked the entry of Node-RED, proving instrumental in building user interfaces for controlling robotic automation equipment, quickly and efficiently, improving communication, and providing seamless control.

# Environmental Considerations

Manufacturing environments, particularly those involving electro-coating processes in plating labs with high humidity and corrosion, presented unique challenges. However, Node-RED's adaptability allowed Abrasive Technology to address these concerns effectively. Dudley emphasizes, "Environmental considerations are crucial. Node-RED facilitates placing our in-house control equipment in sealed boxes to ensure longevity."

# Hardware Challenges and Solutions

Abrasive Technology initially utilized Raspberry Pis for hosting Node-RED instances, linking them to industrialized touch screens for Human-Machine Interfaces (HMIs). While Raspberry Pis proved reliable for many applications, certain projects pushed hardware capabilities. Dudley highlights: "I have found them to be very reliable, but on the current project, I'm absolutely bumping up against its hardware capabilities." The anticipation of the Pi5, with enhanced capabilities, holds promise, and Dudley is eagerly awaiting its arrival.

In addition to Raspberry Pis, Abrasive Technology currently operates a server running Node-RED locally alongside instances on FlowFuse. The company is actively transitioning its Node-RED instances from locally maintained servers to FlowFuse Cloud to make it easier to manage them. Dudley notes, "We also currently have a server Running Node-RED locally as well as instances on FlowFuse. Our search for a better way to host and manage our Node-RED instances is what started our transition to using FlowFuse."

# Impact on Business Operations

Node-RED's integration has significantly impacted Abrasive Technology's business operations. Dudley notes, "Node-RED has immensely facilitated our work. The tool's versatility and development speed have allowed Abrasive Technology to tackle projects that might have been deemed out-of-reach or discouraging in the past. It also allows us to develop our applications in a platform agnostic way that is much more flexible and agile in terms of hardware selection and adaptability.”

# Future Prospects

As Abrasive Technology looks towards the future, Dudley expresses excitement about Node-RED's ongoing development. The ability to create custom nodes and contribute to the community adds to its appeal. Dudley concludes, "I see great potential in the ongoing development and look forward to utilizing it more extensively."

# Conclusion

This case study stands as a testament to how Abrasive Technology, through strategic technological integration, has transformed its manufacturing processes. By addressing challenges, streamlining communication, and embracing innovation, Abrasive Technology sets an inspiring example for the manufacturing industry's continuous evolution.

Challenge

Optimise the production of precision abrasive materials.

Solution

Rapid development of command and monitoring systems using Node-RED hosted on FlowFuse.

Results

- Significant impacted on Abrasive Technology's business operations

- Delivered projects which previously may have not been practical